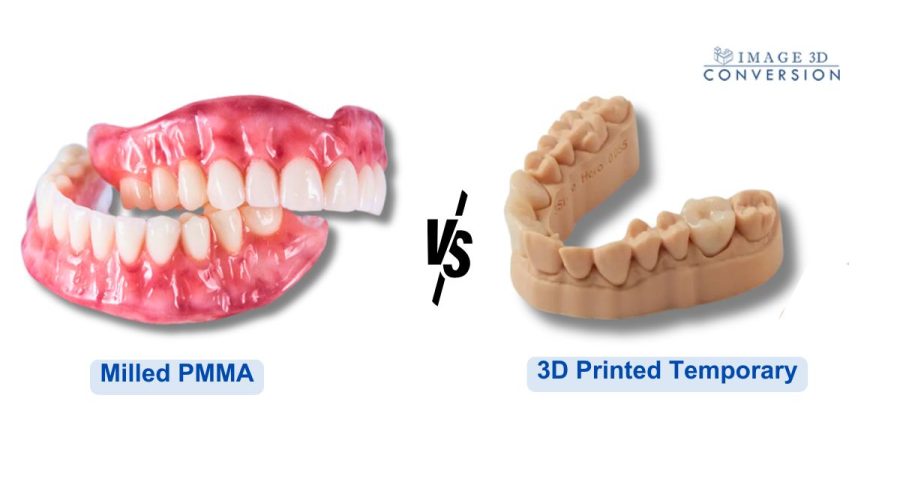

The use of milled PMMA and 3D printing technologies represent significant advancements in digital dentistry. They have gained significant attention in creating dental prosthetics, offering unique benefits for creating high-quality, durable, and aesthetically pleasing restorations.

Milled PMMA is particularly noted for its strength and long-term viability in implant-supported applications, while 3D printing offers customization and efficiency advantages. The choice between these technologies often depends on specific clinical needs and patient preferences.

What are Milled PMMA Temporaries?

Milled PMMA temporaries are dental prosthetics made from polymethyl methacrylate (PMMA) that are fabricated using CAD/CAM (computer-aided design and computer-aided manufacturing) technology. It is a biocompatible acrylic material commonly used in dentistry for creating temporary crowns, bridges, and other dental prosthetics.

Milled PMMA temporaries are specifically designed for use as interim prostheses during the healing phase or until a final restoration can be placed. They provide a high-quality, precise, and aesthetically pleasing solution for patients needing temporary dental restorations.

What are 3D Printed Temporaries?

3D printed temporaries are temporary dental restorations fabricated using 3D printing technology. These temporary crowns, bridges, or other prosthetics are created using CAD software and then printed using compatible 3D printers and dental resins.

They are designed to serve as provisional solutions for patients while permanent dental restorations are being made. 3D printed temporaries use modern digital technology to give dentists a quick, flexible, and affordable way to create high-quality temporary dental restorations.

| Feature | Milled PMMA | 3D Printed Temporaries |

| Aesthetic Quality | Better color stability, long-lasting. | Less stable, best for short-term use. |

| Strength | Stronger, durable for long-term use. | Weaker, suitable for short-term use. |

| Fit and Precision | Highly precise, consistent fit. | Very precise, customizable fit. |

| Production Time | Slower but reliable. | Faster, ideal for urgent cases. |

| Cost | More expensive, worth it for long-term | More affordable, great for temporary needs. |

Milled PMMA vs. 3D Printed Temporaries: Full Comparisons

Both milled PMMA and 3D printed temporaries are popular methods for creating temporary dental restorations. Each method has distinct characteristics, advantages, and limitations making them suitable for different clinical situations.

Aesthetic Quality

Milled PMMA: It can be tinted to match natural teeth. It demonstrates superior color stability compared to 3D printed PMMA, which is important for aesthetic restorations.

3D Printed PMMA: Generally shows less color stability, which can be influenced by various factors, including patient habits and environmental conditions.

Strength and Durability

Milled PMMA: Milled PMMA is typically stronger and more durable than 3D printed temporaries, making it ideal for longer-term use and situations requiring high resilience.

3D Printed Temporaries: 3D printed temporaries generally have lower strength and durability, making them better suited for shorter-term or less demanding applications.

Fit and Precision

Milled PMMA: It offers high precision, as modern milling machines are capable of very accurate cuts. The final restoration typically fits well, closely matching the digital design. The fit is usually very precise, as long as the design and milling process are accurately controlled.

3D Printed Temporaries: It offers high levels of precision, often comparable to or exceeding traditional milling methods. The digital design allows for highly customized restorations, which can be fine-tuned to the patient’s specific needs. This can result in a superior fit, especially with advanced printers and resins.

Time and Convenience

Milled PMMA: The milling process can be time-consuming, and the need for additional adjustments may extend the time needed for fitting.

3D Printed Temporaries: 3D printing is typically faster, with quicker turnaround times for creating and fitting the restorations.

Cost Efficiency

Milled PMMA: Cost is typically higher as it requires more expensive equipment and materials. However, the durability and aesthetic quality may justify the investment for many practices.

3D Printed Temporaries: Typically more cost-effective, with lower material costs and reduced production time. This efficiency can enhance patient acceptance and practice profitability.

Customization Options

Milled PMMA: It allows for detailed customization but may be limited by the milling machine’s capabilities.

3D Printed Temporaries: It is highly customizable with advanced digital design options, allowing for precise adjustments.

Patient Comfort and Satisfaction

Milled PMMA: It generally provides high precision and durability, contributing to comfort when well-finished but may require more manual adjustments.

3D Printed Temporaries: It offers excellent precision, customization, and faster production times, often resulting in a more comfortable fit with fewer adjustments.

Clinical Applications

Situations Where Milled PMMA is Preferred

High Durability:

Milled PMMA is preferred when high durability is required, such as for long-term temporary restorations that need to withstand significant chewing forces. It can last for several months without significant wear or discoloration.

Complex Geometry:

Milled PMMA is advantageous for complex geometric shapes where high precision is required. The subtractive manufacturing process of milling often results in a better marginal fit, which is essential for the longevity and functionality of temporary restorations.

High Esthetic Demands:

Milled PMMA can be shaded to closely match the natural teeth, making it a good choice for anterior restorations where aesthetics are important. Its superior color stability helps maintain a natural appearance over time.

Traditional Workflow Integration:

Milled PMMA fits well into traditional dental workflows and is often used in practices with established milling technology.

Situations Where 3D Printed Temporaries Preferred

Rapid Turnaround:

3D printed temporaries are advantageous when a quick turnaround time is crucial. The additive manufacturing process allows for rapid production, often within a single dental visit.

Highly Customized Restorations:

3D printed temporaries offer extensive customization if needed, such as for unique or complex cases that require specific adjustments.

Cost-Effective Solutions:

3D printed temporaries are generally less expensive to produce, making them suitable for practices looking to minimize costs while still providing quality restorations. This can enhance patient acceptance due to lower fees.

Minimal Adjustments Required:

3D printed temporaries are Ideal for situations where the fit is expected to be accurate right out of the printer, reducing the need for manual adjustments.

Complex and Detailed Designs:

For restorations that require intricate designs or unique shapes, 3D printing offers greater flexibility. It is applicable where intricate designs and fine details are required that might be challenging to achieve with traditional milling.

How to Choose Between Milled PMMA and 3D Printed Temporaries

When choosing between milled PMMA and 3D printed temporaries for dental restorations, several factors should be considered including durability, turnaround time, cost, esthetics, and fit. The choice between the two methods should be guided by the specific clinical needs, patient requirements, practice resources, and the desired outcome for the temporary restoration.

Dental practitioners or patients can opt for Milled PMMA when strength, durability, and aesthetic stability are paramount, particularly for long-term applications and posterior restorations. In addition, milled PMMA is more convenient for integration with traditional workflows.

On the other hand, 3D Printed Temporaries can be used when speed, cost-effectiveness, and design flexibility are more critical, such as in same-day restorations or complex cases. It is suitable for trial and mock-up cases in cosmetic dentistry, allowing for quick visualization of treatment outcomes.

Milled PMMA and 3D printed temporaries each have their strengths and weaknesses. The methods have distinct characteristics, advantages, and limitations that make them suitable for different clinical situations.

Image3DConversion: Leading Digital Dentistry Solutions

At Image3DConversion, we offer superior guided surgery services with the latest technology and expert supervision to achieve the best outcomes. Our extensive range includes accurate bone segmentation, comprehensive radiology reports, custom surgical guides, digital dentures, and clear aligner planning.

We are also pioneers in advanced services such as Zygo Planning and 3D printing, providing precise, high-quality results that streamline dental procedures and improve patient care. Choose Image3DConversion for exceptional precision and outstanding dental solutions.

FAQs

Yes, you can use both milled PMMA and 3D-printed temporaries in your practice. Integrating both methods into your practice can enhance your service offerings, improve patient outcomes, and provide flexibility in treatment options.

3D printed temporaries are generally not as durable as milled PMMA temporaries. 3D printed temporaries, while offering excellent precision and customization, often use resins that may not be as durable under heavy use or extended wear.

Milled PMMA Temporaries typically take 6 business days to complete the milling process and prepare the temporary restorations. This includes the design phase and any necessary adjustments before shipping. 3D-printed temporaries can be produced much faster, often within a single dental visit.

References

- CADDENT. (n.d.). “Temporary PMMA.” CADDENT Wiki.

- Lee, H. C., Song, S. H., Kim, D. J., Lee, S. J., Kang, H. W., & Ryu, J. J. (2023). “Mechanical Properties of 3D-Printed Poly(methyl methacrylate) for Dental Applications.” Journal of Advanced Prosthodontics, 15(3), 184-192.

- Akar, T., et al. (2022). “Comparison between Conventional PMMA and 3D Printed Resins for Denture Bases: A Narrative Review.” ResearchGate.

- Kim, D. J., et al. (2021). “Force at Fracture for Self-Cured PMMA, Milled PMMA, and 3D Printed Resin: Experimental Study.” ResearchGate.