Dental Implant Outcomes: The Impact of Accurate 3D Printing Technology

Introduction:

In the realm of modern dentistry, precision and efficacy are paramount, especially in the domain of dental implants. These tiny yet significant fixtures play a pivotal role in restoring smiles and enhancing oral health. With advancements in technology, particularly in the domain of 3D printing, dental implant procedures have undergone a transformative shift. This blog aims to delve into the profound influence of accurate 3D printing on dental implant outcomes, elucidating how this innovative technology is revolutionizing the field of dentistry.

The Evolution of Dental Implants:

Dental implants have emerged as the gold standard for replacing missing teeth due to their durability, functionality, and aesthetic appeal. Traditional methods of fabricating dental implants often involved a laborious and time-consuming process, fraught with limitations in precision and customization. However, the advent of 3D printing technology has catalyzed a paradigm shift in implant dentistry, offering unprecedented levels of accuracy and personalization.

The Role of Accurate 3D Printing:

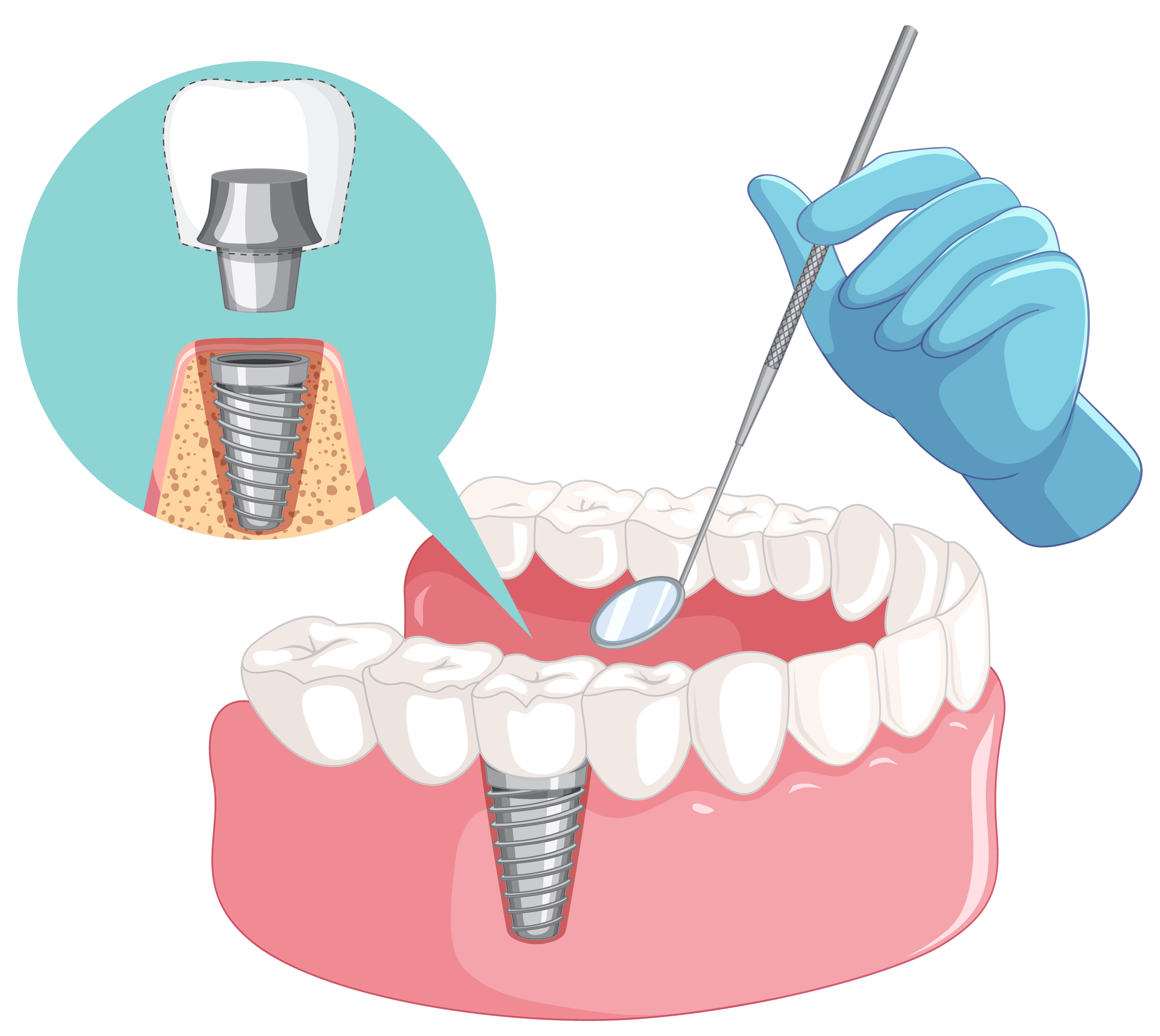

Accurate 3D printing has revolutionized the fabrication process of dental implants by enabling the creation of highly detailed and customized prosthetics tailored to each patient's unique oral anatomy. Utilizing advanced digital imaging techniques such as cone beam computed tomography (CBCT) scans, dental professionals can obtain intricate 3D models of the patient's jawbone structure with unparalleled precision. These digital blueprints serve as the foundation for designing and manufacturing implants that seamlessly integrate with the natural dentition.

Enhanced Precision and Customization:

One of the most significant advantages of accurate 3D printing in dental implantology is its ability to enhance precision and customization. By leveraging computer-aided design (CAD) software, dental practitioners can meticulously plan the implant placement, taking into account factors such as bone density, angulation, and occlusal dynamics. This meticulous planning ensures optimal implant positioning, thereby minimizing the risk of complications such as implant failure or malocclusion.

Furthermore, 3D printing allows for the fabrication of patient-specific surgical guides, which serve as navigational tools during the implant placement procedure. These guides are designed based on the patient's unique anatomy, providing the clinician with real-time guidance to achieve precise implant placement with minimal invasiveness. As a result, patients experience reduced post-operative discomfort and accelerated healing times, leading to enhanced overall outcomes.

Improved Biocompatibility and Longevity:

Another compelling aspect of accurate 3D printing in dental implantology is its ability to utilize biocompatible materials that mimic the natural properties of teeth and bone. Advanced materials such as titanium alloys and bioceramics exhibit excellent osseointegrative properties, allowing the implant to fuse seamlessly with the surrounding bone tissue over time. This enhanced biocompatibility not only ensures long-term stability and functionality but also reduces the risk of adverse reactions or implant rejection.

Moreover, 3D printing enables the fabrication of porous implant surfaces with precisely controlled microstructures, further promoting osseointegration and soft tissue integration. These intricately designed surfaces facilitate the ingrowth of bone cells and vascularization, fostering a robust biological bond between the implant and the surrounding tissues. As a result, patients benefit from implants that exhibit superior strength, stability, and longevity, ensuring reliable long-term outcomes.

Accelerated Treatment Timelines:

In addition to improving the quality and precision of dental implant outcomes, accurate 3D printing technology has also streamlined treatment workflows, leading to accelerated treatment timelines. The integration of digital technologies enables seamless communication and collaboration between dental specialists, including prosthodontists, oral surgeons, and dental laboratory technicians.

Furthermore, the on-demand nature of 3D printing allows for rapid prototyping and production of dental implants, significantly reducing lead times compared to traditional manufacturing methods. This expeditious process translates to shorter waiting periods for patients, enabling them to receive timely and efficient dental implant treatment without compromising on quality or accuracy.

Future Perspectives and Conclusion:

As technology continues to advance at a rapid pace, the influence of accurate 3D printing on dental implant outcomes is poised to become even more profound. Innovations such as bioprinting and regenerative therapies hold the potential to revolutionize implant dentistry further, paving the way for enhanced tissue regeneration and personalized treatment modalities.

In conclusion, accurate 3D printing technology represents a game-changer in the field of dental implantology, offering unparalleled levels of precision, customization, and biocompatibility. By harnessing the power of digital innovation, dental professionals can deliver superior implant outcomes that enhance patient satisfaction, oral function, and quality of life. As we embark on this exciting journey of technological advancement, the future of dental implantology shines brighter than ever before.

DOWNLOAD FREE E-BOOK

Kick start your Guided Surgery Practice.

USA & Canada:

USA & Canada:

UK:

UK:

Comments: